1-815-344-2222

DeMarco® Industrial Vacuum Corporation

Engineering For A Cleaner Tomorrow™

The DeMarco name has been synonymous with setting the industry standard since Thomas M. DeMarco was awarded the first industrial vacuum patent in the 1960's utilizing high suction PD vacuum pump technology.

Partner with DeMarco's 50 years of engineering expertise to solve your challenging clean up applications.

Portable Industrial Vacuums

Versatile and compact vacuum designs with roll-dump collection hoppers. HEPA Option Available.

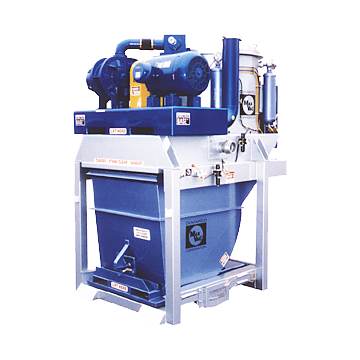

Stationary Industrial Vacuums

Stand-alone or Central turnkey vacuum systems offering various Bottom-Dump Hopper configurations. HEPA Option Available.

MAXceptor™ Cyclone Pre-Separators

Separate the bulk of materials from the air stream from a single vacuuming source.

Custom Engineered Vacuums

Our team of project engineers will successfully meet the exact requirements of your unique application. HEPA Option Available.

OSHA Compliant Vacuum Systems

Combustible Dust Vacuums

Speak With A Sales Engineer